Sling Tension Calculator

Why sling tension deserves more attention on the work site

If you’re working with angled slings, here’s one thing that might surprise you, the force on each sling leg is often way more than the actual load weight. Why? Because sling tension goes up as the angle between the sling and the vertical gets larger, a detail that’s easy to overlook, but critical for safety.

This is why understanding sling tension isn’t just for engineers. It’s a must for anyone planning or executing a lift, whether you're onshore, offshore, or in a fabrication yard

What’s really going on with sling tension

Unless your slings are hanging perfectly vertical (which almost never happens), the force in each sling leg is going to be more than just half or a quarter of the load. Why? Because once you start angling slings away from vertical, you introduce horizontal force into the equation. And that added force cranks up the tension in each sling leg.

Here’s the formula most riggers use to get a handle on it:

- Load = total weight being lifted

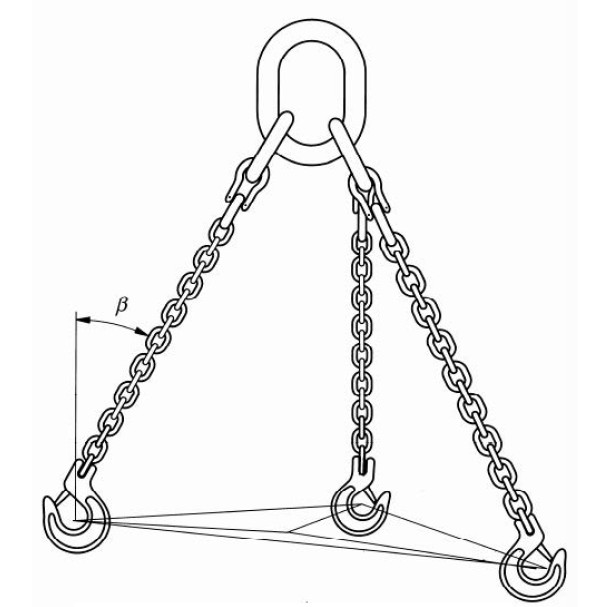

- Number of Legs = usually 2, 3, or 4

- Angle = measured from the vertical, not the horizontal

Let’s take an example:

You’re lifting 2,000 kg with a two-leg sling setup at a 30° angle from vertical. That gives you a cosine factor of about 0.87.

Plug it into the formula:

Now increase the angle, say to 60° from vertical and tension doubles to 2,000 kg per leg. That’s why rigging pros keep sling angles as steep as possible, ideally between 45°-60°, to reduce tension and keep the load stable.

Why sling tension calculations matter

Getting sling tension right can be the difference between a clean lift and a catastrophic failure. Here's what it helps you avoid:

- Overloaded slings or shackles

- Bent hooks or distorted lifting points

- Dropped loads or near-misses

- Violations of standards like EN 1492.

In short? Calculating tension isn't just about math, it’s about protecting people, equipment, and the job timeline.

What affects sling tension?

It’s not just the weight. These factors also play a big role:

- The load’s center of gravity

- Number of sling legs (and whether the load is evenly distributed)

- Sling angle from vertical

- The spacing between lifting points

- The type of sling (webbing, wire rope, chain, etc.)

Even sling stretch can throw things off if you’re not accounting for it.

Let our rigging engineers help you get it right

Planning a tricky lift? Working with tight angles or odd load shapes? Our engineering team is here to help you make the right call. We can assist with:

- Full rigging reviews

- Sling sizing and tension guidance

- Custom lift plans

- Guidance to keep you in line with EN, ISO, and LOLER standards.