Choosing the right steel wire rope

How can you select the appropriate steel wire rope?

A properly chosen steel wire rope ensures the longest possible service life, given that the wire is maintained through inspection and proper lubrication. When purchasing your new steel wire rope, make sure it's the correct type, construction, dimension, and length. Follow the machine manufacturer's recommendations and ensure that the equipment matches the appropriate machine group/grade.

Rotation resistance

To reduce the likelihood of rotation, particularly at elevated lifting heights, it is advisable to utilize ropes labeled as "rotation resistant" or "Low Rotation". Rotation resistant ropes are constructed with multiple layers of strands, each layer laid in the opposite direction to the next layer. This arrangement ensures that the torque in the various layers counteracts the opposing forces within the rope.

What is a minimum breaking load?

Minimum breaking load (MBL) - The minimum breaking load of a wire rope results from the calculated breaking strength of the rope multiplied by the stranding factor. The actual breaking force of a wire rope is the breaking force that was determined when the rope was subjected to a breaking test.

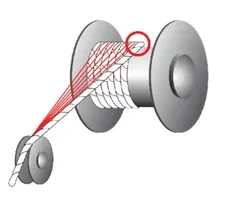

The fleet angle

Excessive fleet angle can result in increased rope wear against the adjacent flange on the drum, potentially leading to torsional issues.

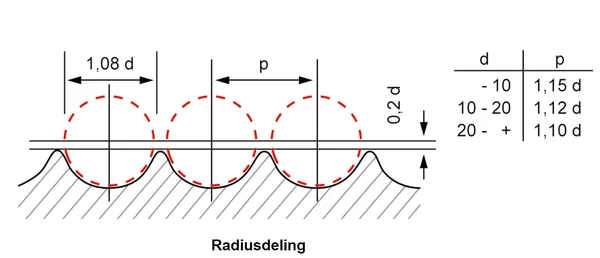

Wire rope sheaves

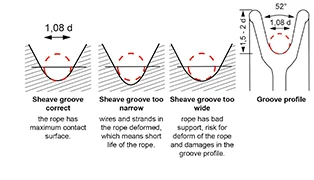

Wire rope sheaves should support the rope along approx. 1/3 of its circumference. We recommend a groove diameter of 1,08 x d, where d = nominal wire rope diameter.

Before installing a new rope, it is important to inspect the sheave grooves, layers, and lubrication. To begin, measure the groove diameter using a radius gauge and assess the overall condition of the groove. The groove diameter should ideally fall within a range of the nominal rope diameter plus 8% to 14%, which translates to (0,54 x d to 0,57 x d)

Lubrication & Maintenance

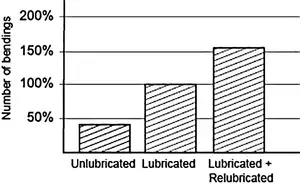

During operation, steel wire ropes experience wear as the individual wires rub against each other. To mitigate friction, lubrication is applied during manufacturing. This lubrication enhances the performance of the steel wire rope and prolongs its service life.

Immediately after installation, it is crucial to inspect the lubrication of the rope and remove any debris such as sand and dirt. Additionally, if necessary, the wire rope should be supplemented with lubrication before use. Furthermore, it's imperative to schedule regular lubrication intervals based on the prevailing operational conditions to ensure optimal functionality.

Do you want to learn more?

Contact us or read more articles about steel wire ropes.