Origin of MRT

The beginning of magnetic rope testing

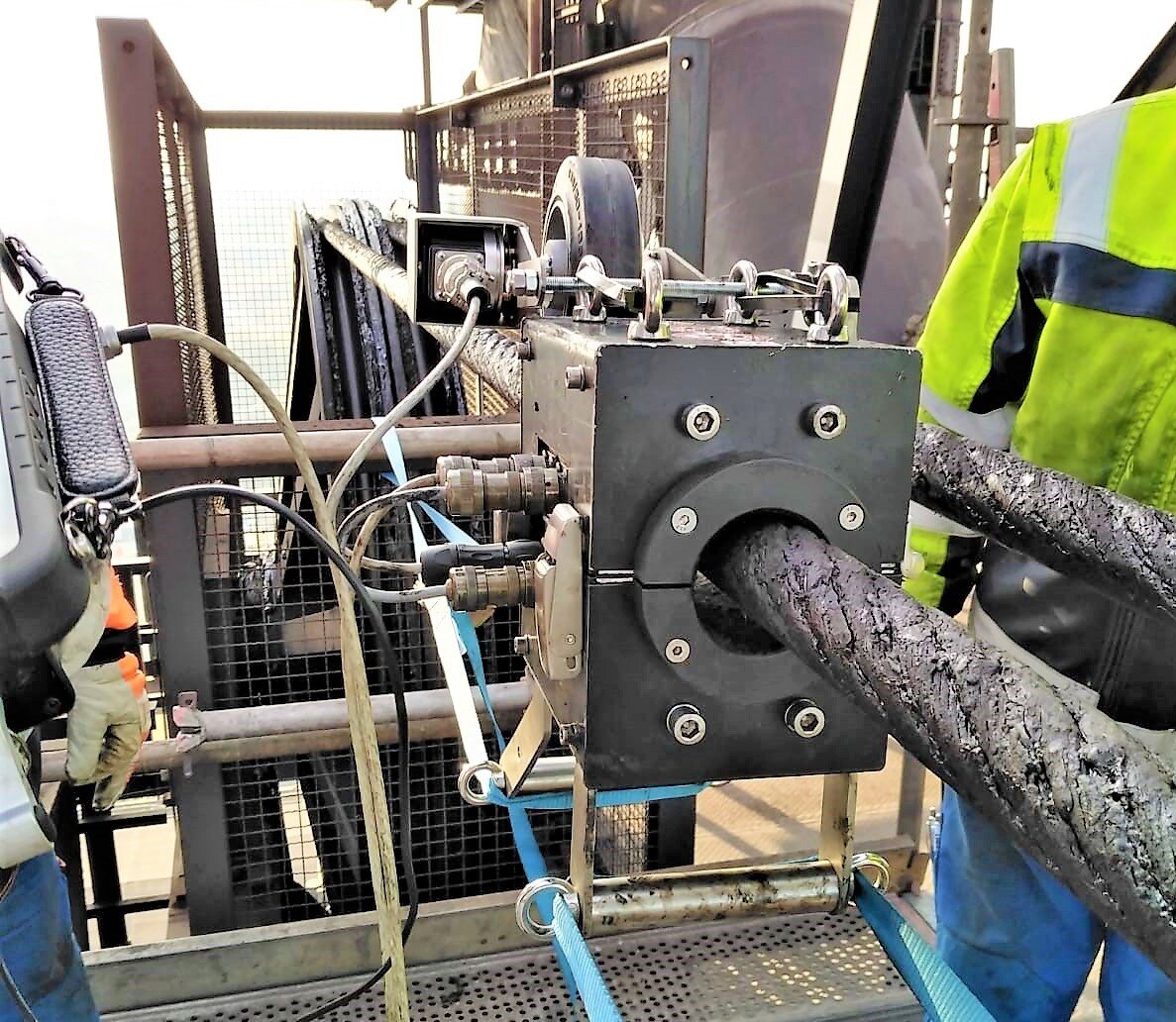

MRT was once introduced in the ropeway industry to identify external as well as internal defects and provide maximum protection to passengers. Magnetic rope testing first came into use in this sector in the 1980s, especially for special use cases. The technique later caught on in the offshore heavy lift market due to increasing demands in terms of efficiency and safety.

In the meantime, magentic rope testing has become exceedingly well established, so that the latest version of ISO4309 already includes magentic rope testing as a common assessment method for the inspection of general steel wire ropes.

The innovative magentic rope testing concept is continuously evolving: the magnetic induction method as well as the user interface are steadily improving, so that a complete steel wire rope inspection can now be performed completely automatically.

Magnetic Rope Testing & Heavy Lifting

Although heavy duty ropes do not lift people but loads, safety is extremely important as failure can even cause disaster (imagine a steel mill or a mine).

A strong advance in technology led to the availability of heavy-duty lifting equipment that complies with cableway standards in the early 2000s. In the latest version of ISO4309 (2017), magentic rope testing is mentioned as the state-of-the-art method for internal damage.

Low-rotation steel wire ropes are actually used in many applications. Low-twist steel wire ropes behave differently depending on the rope layer. Often, degradation begins inside the rope, and standard visual inspection is not sufficient to ensure proper evaluation. In these cases, an magentic rope testing is strongly recommended to avoid failures and damage.