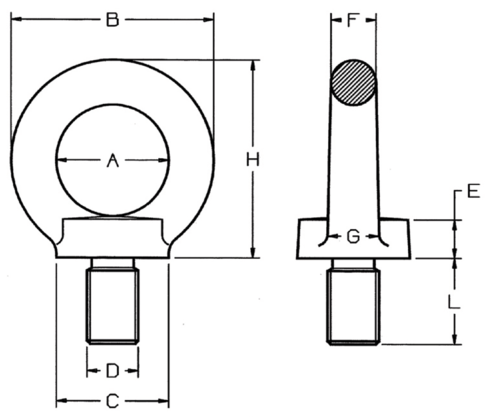

Lifting eye bolt to be screwed by hand.

- Material: Alloy steel 8.8.

- Marking: CE-marked, Marked with WLL, sizes, steel quality, producername, tracability.

- Finish: Red painted.

- Note: Approved for lifting.

- Warning: The lifting eye bolts shall be screwed tight against the surface. When two lifting eyes are used their mutual position shall result in the two eyes at the same level. Larger angle between the slings than 90° are not tolerated. Lifting eye bolts can not be assembled against a surface that differs essentially from a surface perpendicular to the direction of the lift

- Safety factor: 4:1

- Grade: 8